"Kulula" kungase kungabi igama elifikayo engqondweni ngokuklama izindawo ezinjalo ezibucayi. Nokho, lokho akusho ukuthi awukwazi ukukhiqiza umklamo oqinile wegumbi elihlanzekile ngokubhekana nezinkinga ngokulandelana okunengqondo. Lesi sihloko sihlanganisa isinyathelo ngasinye esingukhiye, kwehle kuya kumathiphu aphathekayo aqondene nohlelo lokusebenza okulungisa izibalo zomthwalo, ukuhlela izindlela zokucwenga, kanye nokukhomba indawo eyanele yegumbi eliwumshini ngokuhlobene nekilasi legumbi lokuhlanza.

Izinqubo eziningi zokukhiqiza zidinga izimo zemvelo eziqinile ezihlinzekwa yindlu yokuhlanza. Ngenxa yokuthi amagumbi okuhlanza anezinhlelo zemishini eziyinkimbinkimbi kanye nezindleko eziphezulu zokwakha, ukusebenza, namandla, kubalulekile ukwenza umklamo wegumbi lokuhlanza ngendlela ehlelekile. Lesi sihloko sizokwethula indlela yesinyathelo ngesinyathelo yokuhlola nokuklama amagumbi okuhlanza, ukufaka izinto kubantu/ukugeleza kwezinto, ukuhlukaniswa kokuhlanzeka kwesikhala, ukucindezelwa kwesikhala, ukugeleza komoya wendawo, ukukhishwa komoya wesikhala, ibhalansi yomoya wesikhala, okuguquguqukayo okufanele kuhlolwe, ukukhethwa kwesistimu yemishini, izibalo zomthwalo wokushisa / wokupholisa, kanye nezidingo zesikhala sokusekela.

Isinyathelo sokuqala: Hlola Isakhiwo Sabantu/Ukugeleza Kwempahla

Kubalulekile ukuhlola abantu nokugeleza kwezinto ezibonakalayo ngaphakathi kwegumbi elihlanzekile. Izisebenzi zasegumbini elihlanzekile ziwumthombo omkhulu wokungcoliswa kwegumbi futhi zonke izinqubo ezibucayi kufanele zihlukaniswe neminyango nezindlela zokufinyelela kubasebenzi.

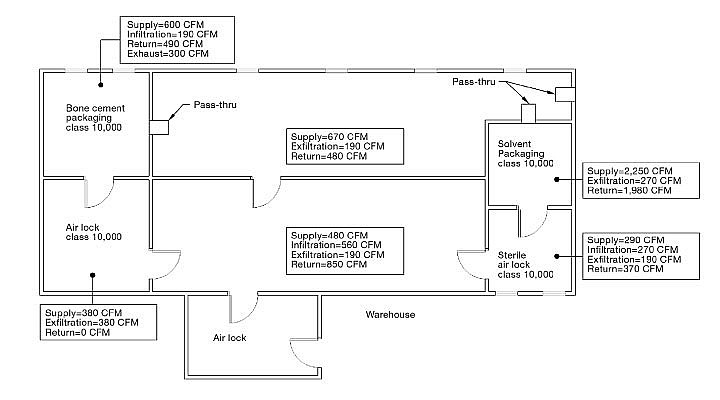

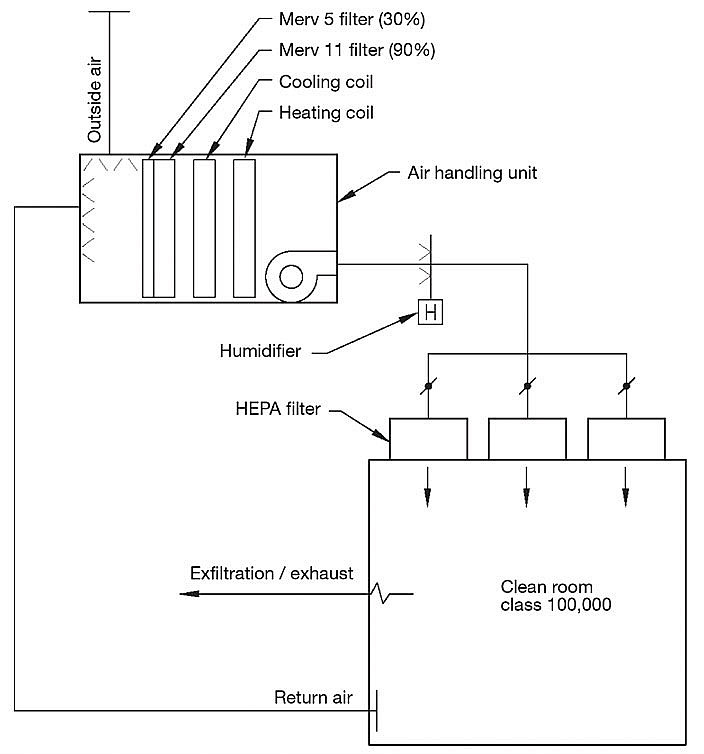

Izindawo ezibaluleke kakhulu kufanele zibe nokufinyelela okukodwa ukuvimbela isikhala ekubeni indlela eya kwezinye, izindawo ezingabalulekile kangako. Ezinye izinqubo zemithi kanye ne-biopharmaceutical zisengozini yokungenwa izifo ezihlukahlukene ezivela kwezinye izinqubo zemithi kanye ne-biopharmaceutical. Inqubo yokungcoliswa kwezinhlamba idinga ukuhlolwa ngokucophelela ukuze kutholwe imizila yezinto ezingavuthiwe zokungena kanye nokubamba, ukuhlukaniswa kwenqubo yezinto ezibonakalayo, nezindlela zokuphuma komkhiqizo oqediwe kanye nokubamba. Umfanekiso 1 uyisibonelo sendawo yesimende yamathambo enezinto zombili zenqubo ebucayi ("I-Solvent Packaging", "Bone Cement Packaging") izikhala ezinokufinyelela okukodwa kanye nezikhiya zomoya njengezivimbela ezindaweni eziphezulu zethrafikhi yabasebenzi ("Ingubo", "I-Ungown").

Isinyathelo Sesibili: Thola Ukuhlukaniswa Kokuhlanzeka Kwesikhala

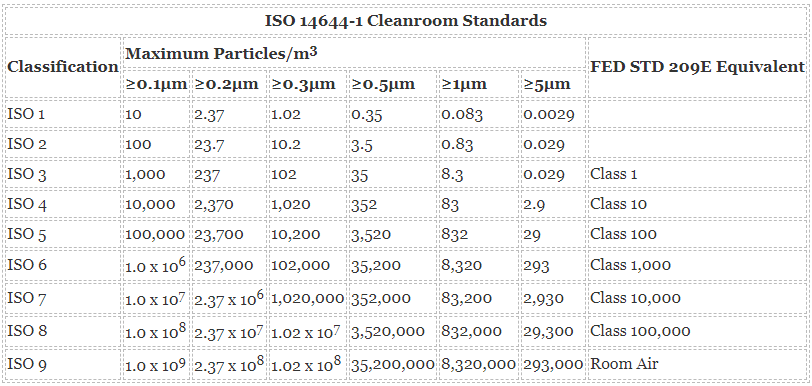

Ukuze ukwazi ukukhetha ukuhlukaniswa kwegumbi elihlanzekile, kubalulekile ukwazi izinga eliyisisekelo lokuhlukaniswa kwegumbi elihlanzekile nokuthi ziyini izidingo zokusebenza zengxenye ngayinye yokuhlanzeka. I-Institute of Environmental Science and Technology (IEST) Standard 14644-1 inikeza izigaba zokuhlanzeka ezihlukene (1, 10, 100, 1,000, 10,000, kanye ne-100,000) kanye nenani elivumelekile lezinhlayiya ezinosayizi wezinhlayiyana ezihlukene.

Isibonelo, igumbi lokuhlanza Lekilasi 100 livunyelwe ubuningi bezinhlayiya ezingu-3,500/cu ft kanye nama-microns angu-0.1 nangaphezulu, izinhlayiya ezingu-100/cubic ft. kuma-microns angu-0.5 nangaphezulu, kanye nezinhlayiyana ezingu-24/cubic ft. ku-1.0 microns nangaphezulu. Leli thebula linikeza ukuminyana kwezinhlayiyana zomoya okuvumelekile ngokwethebula lokuhlukanisa lokuhlanzeka:

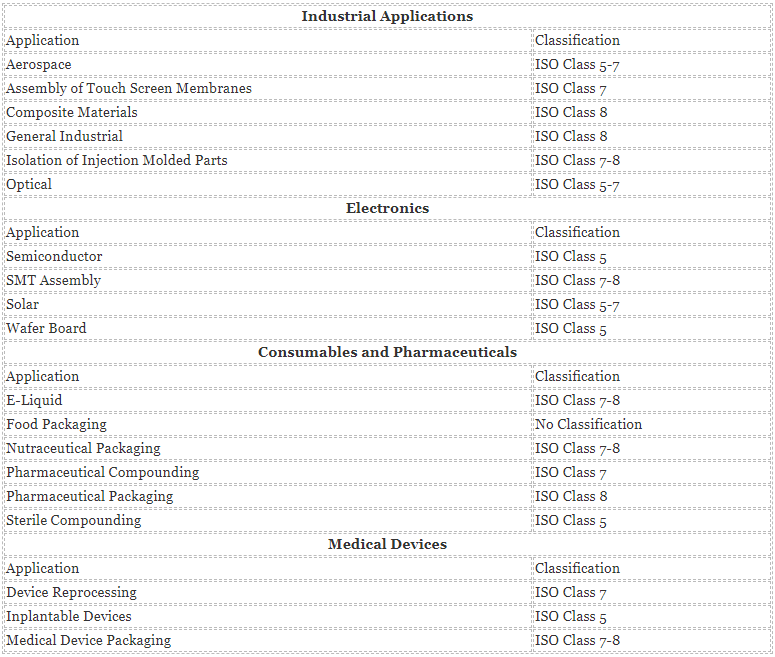

Ukuhlukaniswa ngezigaba zokuhlanzeka kwendawo kunomthelela omkhulu ekwakhiweni kwegumbi elihlanzekile, ukunakekelwa, kanye nezindleko zamandla. Kubalulekile ukuhlola ngokucophelela amazinga okwenqaba/ukungcola ezigabeni ezihlukene zokuhlanzeka nezimfuneko ze-ejensi elawulayo, njenge-Food and Drug Administration (FDA). Ngokuvamile, lapho inqubo izwela kakhulu, kufanele kusetshenziswe ukuhlukaniswa okuqinile kwenhlanzeko. Leli thebula lihlinzeka ngezigaba zokuhlanzeka zezinqubo ezihlukahlukene zokukhiqiza:

Inqubo yakho yokukhiqiza ingase idinge isigaba senhlanzeko esiqinile ngokuya ngezidingo zayo ezihlukile. Qaphela lapho unikeza izigaba zokuhlanzeka endaweni ngayinye; akumele kube nama-oda angaphezu kwamabili omehluko wobukhulu ekuhlukaniseni ukuhlanzeka phakathi kwezikhala zokuxhuma. Isibonelo, akwamukelekile ukuthi igumbi elihlanzekile Lekilasi 100,000 livuleke libe yigumbi elihlanzekile Lekilasi Le-100, kodwa kuyamukeleka ukuthi igumbi lokuhlanza Lekilasi elingu-100,000 livuleke libe igumbi elihlanzekile Lekilasi elingu-1,000.

Uma sibheka indawo yethu yokupakisha usimende wamathambo (Umfanekiso 1), “Ingubo”, Impahla Engangeni ndawo” kanye “Nepaki Yokugcina” ayizikhala ezibaluleke kakhulu futhi zinezigaba zokuhlanzeka zeSigaba 100,000 (ISO 8), “I-Bone Cement Airlock” kanye “Ne-Sterile Airlock” evuleleke ezikhaleni ezibucayi futhi ibe ne-Class 0 (Cenement 7); Ukupakisha” kuyinqubo ebucayi enothuli futhi inesigaba senhlanzeko Yekilasi 10,000 (ISO 7), futhi i-'Solvent Packaging” iyinqubo ebucayi kakhulu futhi yenziwa ku-Class 100 (ISO 5) laminar flowhoods egumbini lokuhlanza le-Class 1,000 (ISO 6).

Isinyathelo Sesithathu: Nquma I-Space Pressurization

Ukugcina umfutho wendawo yomoya omuhle, maqondana nezindawo zokuhlukaniswa kwenhlanzeko eseduze, kubalulekile ekuvimbeleni ukungcola ekungeneni endlini ehlanzekile. Kunzima kakhulu ukugcina ukuhlanzeka kwesigaba ngokungaguquki uma kunokucindezela kwesikhala okungathathi hlangothi noma okungekuhle. Kufanele ube yini umehluko wengcindezi yesikhala phakathi kwezikhala? Ucwaningo oluhlukahlukene luhlole ukungena kokungcola egumbini elihlanzekile uma kuqhathaniswa nomehluko wengcindezi yesikhala phakathi kwegumbi elihlanzekile nendawo engalawulwayo exhumene nayo. Lezi zifundo zithole umehluko wengcindezi we-0.03 kuya ku-0.05 ku-wg ukuze uphumelele ekunciphiseni ukungena okungcolile. Ukwehluka kwengcindezi yesikhala ngaphezu kuka-0.05 in. wg akunikezeli ngokulawula okungcolisayo okungcono kakhulu bese kuba ngu-0.05 in. wg

Khumbula, umehluko wengcindezi yendawo ephakeme unezindleko zamandla aphezulu futhi kunzima kakhulu ukuwulawula. Futhi, umehluko wengcindezi ephakeme udinga amandla amaningi ekuvuleni nasekuvaleni iminyango. Umehluko omkhulu onconyiwe wengcindezi yonkana emnyango ngu-0.1 in. wg ku-0.1 in. wg, umnyango wezinyawo ezingu-3 ngo-7 udinga amaphawundi angu-11 wamandla ukuze uvule futhi uvale. I-cleanroom suite ingase idinge ukulungiswa kabusha ukuze kugcinwe umehluko we-static pressure kuyo yonke iminyango ngaphakathi kwemikhawulo eyamukelekayo.

Indawo yethu yokupakisha usimende wamathambo yakhiwa ngaphakathi kwendawo yokugcina impahla ekhona, enengcindezi yesikhala emaphakathi (0.0 in. wg). Isikhiya somoya phakathi kwendlu yokugcina impahla kanye "Nengubo/I-Ungown" ayinakho ukuhlukaniswa kwenhlanzeko yesikhala futhi ngeke ibe ne-pressurization yesikhala esimisiwe. I-"Gown / Ungown" izoba ne-pressurization yesikhala ye-0.03 in. wg "I-Bone Cement Air Lock" kanye ne-"Sterile Air Lock" izoba ne-pressurization yesikhala ye-0.06 in. wg "I-Final Packaging" izoba ne-pressurization yesikhala ye-0.06 in. wg "I-Bone Cement Packaging.03" izoba nesikhala esiphansi se-space. ingcindezi kune-'Bone Cement Air Lock" kanye "ne-Final Packaging" ukuze kuqukethwe uthuli olukhiqizwa ngesikhathi sokupakisha.

Ukuhlunga komoya ku-'Bone Cement Packaging' kuvela esikhaleni esinezigaba zokuhlanzeka okufanayo.Ukungena komoya akufanele kusuke endaweni yokuhlukanisa inhlanzeko engcolile kuye endaweni yokuhlukanisa inhlanzeko ehlanzekile.I-"Solvent Packaging" izoba nokucindezela kwesikhala okungu-0.11 in. wg Qaphela, umehluko wengcindezi yesikhala ku-0.0 phakathi kwesikhala esibucayi kakhulu phakathi kwe-0. Okubalulekile "Ukupakishwa Kwe-Solvent" kanye "Ne-Sterile Air Lock" kungu-0.05 in. wg Ukucindezela kwesikhala esingu-0.11 in. wg ngeke kudinge ukuqinisa okukhethekile kwesakhiwo sezindonga noma usilingi wokucindezela kwesikhala ngaphezu kuka-0.5 in.

Isinyathelo Sesine: Nquma Ukugeleza komoya Kokuhlinzeka Ngesikhala

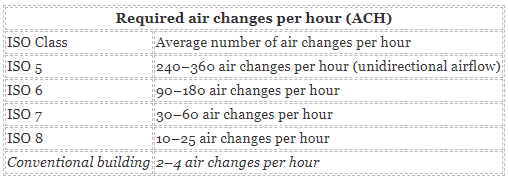

Ukuhlukaniswa kwenhlanzeko yesikhala kuwukuhluka okuyinhloko ekunqumeni ukugeleza komoya kwegumbi elihlanzekile. Uma ubheka ithebula lesi-3, isigaba ngasinye esihlanzekile sinezinga lokushintsha komoya. Isibonelo, igumbi lokuhlanza Lekilasi 100,000 linobubanzi obuyi-15 kuya ku-30 ach. Izinga lokushintsha komoya le-cleanroom kufanele licabangele umsebenzi olindelwe ngaphakathi kwegumbi lokuhlanza. Igumbi lokuhlanza le-Class 100,000 (ISO 8) elinenani eliphansi lokuhlala, inqubo ephansi yokukhiqiza izinhlayiya, kanye nokucindezela okuhle kwendawo ngokuhlobene nezindawo eziseduze zokuhlanzeka okungcolile kungase kusebenzise i-15 ach, kuyilapho igumbi lokuhlanza elifanayo elihlala abantu abaningi, ukungena / ukuphuma njalo, inqubo yokukhiqiza izinhlayiya eziphezulu, noma cishe kuzodinga ukucindezela kwesikhala.

Umklami udinga ukuhlola uhlelo lwakhe oluqondile futhi anqume izinga lokushintsha komoya okufanele lisetshenziswe. Ezinye izinto eziguquguqukayo ezithinta ukugeleza komoya kokunikezwa kwesikhala ukugeleza komoya kwenqubo yokukhipha umoya, ukungena komoya ngeminyango/izivulo, nomoya ophumela ngaphandle ngeminyango/izikhala. I-IEST ishicilele amanani okushintsha umoya anconyiwe ku-Standard 14644-4.

Uma ubheka Umfanekiso woku-1, “Ingubo/Yokungagqoki” ibe nokuhamba okuningi kokungena/ngaphandle kodwa akusona isikhala esibalulekile, okuholela ku-20 a ch., 'Sterile Air Lock” kanye “neBone Cement Packaging Air Lock” akhelene nezikhala ezibucayi zokukhiqiza futhi esimweni se-“Bone Cement Packaging Air Lock” isuka emoyeni ivala isikhala, ivala isikhala somoya. banokuhamba okulinganiselwe kokungena/ukuphuma futhi azikho izinqubo zokukhiqiza izingxenye ezithile, ukubaluleka kwazo okubalulekile njengesivimbeli phakathi “kwengubo/yokungagqoki” kanye nezinqubo zokukhiqiza kuholela ekubeni babe nama-ach angama-40.

"I-Final Packaging" ibeka izikhwama ze-bone Cement / Solvent kuphakheji yesibili engabalulekile futhi iphumela ku-20 ach rate. I-"Bone Cement Packaging" iyinqubo ebucayi futhi inezinga le-40 ach. I-'Solvent Packaging” iyinqubo ebucayi kakhulu eyenziwe kuma-laminar e-Class 100 (ISO 5) ngaphakathi kwegumbi lokuhlanza le-Class 1,000 (ISO 6). I-'Solvent Packaging” inomkhawulo kakhulu wokuhamba nokuphuma kanye nenqubo ephansi yokukhiqiza izingxenye zezinhlayiyana, okuholela esilinganisweni esingu-150 ach.

Ukwahlukaniswa Kwegumbi Elihlanzekile kanye Nezinguquko Zomoya Ngehora

Ukuhlanzeka komoya kutholakala ngokudlulisela umoya ngezihlungi ze-HEPA. Lapho umoya udlula kaningi kuzihlungi ze-HEPA, izinhlayiya ezimbalwa zisala emoyeni wegumbi. Umthamo womoya ohlungiwe ngehora elilodwa ohlukaniswe umthamo wekamelo unikeza inani lezinguquko zomoya ngehora.

Izinguquko zomoya eziphakanyiswe ngenhla ngehora ziwumthetho wokuklama wesithupha kuphela. Kufanele zibalwe ngekhompyutha uchwepheshe we-HVAC cleanroom, njengoba izici eziningi kufanele zicatshangelwe, njengosayizi wegumbi, inani labantu egumbini, okokusebenza okusegumbini, izinqubo ezihilelekile, ukuzuza ukushisa, njll.

Isinyathelo Sesihlanu: Thola Ukugeleza Kokukhishwa Komoya Wendawo

Iningi lamagumbi ahlanzekile angaphansi kwengcindezi eyakhayo, okuholela ekutheni umoya ohleliwe ungene ezindaweni ezixhumene ezinomfutho ophansi omile kanye nokuphuma komoya okungahleliwe ngezindawo zikagesi, izinto ezilungiswayo zokukhanya, amafreyimu amafasitela, amafreyimu eminyango, isixhumi esibonakalayo odongeni/ephansi, isixhumi esibonakalayo sodonga/uphahla, nezicabha zokungena. Kubalulekile ukuqonda ukuthi amakamelo awavalwanga kahle futhi avuza. Igumbi lokuhlanza elivalwe kahle lizoba nesilinganiso sokuvuza sevolumu esingu-1% kuya ku-2%. Ingabe lokhu kuvuza kubi? Akunjalo.

Okokuqala, akunakwenzeka ukuba nokuvuza kwe-zero. Okwesibili, uma kusetshenziswa amadivaysi okulawula umoya, ukubuyisela, nokukhipha umoya, kudingeka kube nomehluko omncane ongu-10% phakathi kokunikezwa nokubuyisela ukugeleza komoya ukuze kunqanyulwe ngokwezibalo ukuhlinzeka, ukubuyisela, kanye nokukhipha amavalvu omoya ukusuka kwelinye. Inani lomoya ophumela eminyango lincike kusayizi womnyango, umehluko wengcindezi kuwo wonke umnyango, nokuthi umnyango uvalwe kahle kangakanani (ama-gaskets, amaconsi eminyango, ukuvalwa).

Siyazi ukuthi umoya ohleliwe wokungena/wokukhipha usuka endaweni eyodwa uye kwesinye. Kuphi ukuthululwa okungahleliwe? Umoya ukhulula ngaphakathi kwesikhala se-stud nangaphezulu. Uma sibheka iphrojekthi yethu yesibonelo (Umfanekiso 1), ukukhishwa komoya ngomnyango we-3- by 7- foot yi-190 cfm enengcindezi ehlukile ye-static ye-0.03 ku-wg kanye ne-270 cfm ene-differial static pressure ye-0.05 in. wg

Isinyathelo Sesithupha: Thola Ibhalansi Yomoya Yemkhathi

Ibhalansi yomoya wesikhala ihlanganisa ukwengeza konke ukugeleza komoya esikhaleni (ukunikezwa, ukungena) kanye nakho konke ukugeleza komoya okushiya isikhala (i-exhaust, exfiltration, return) ilingana. Uma ubheka ibhalansi yomoya yesikhala sesikhungo sethambo sikasimende (Umfanekiso 2), “I-Solvent Packaging” inokuhanjiswa komoya okungu-2,250 cfm kanye no-270 cfm wokungcola komoya ku-'Sterile Air Lock", okuholela ekubuyeni komoya okungu-1,980 cfm. 'I-Solvent Packaging', kanye nokukhishwa kwe-190 cfm ku-“Gown/Ungown”, okuholela ekubuyeni komoya okungu-370 cfm.

I-“Bone Cement Packaging” ino-600 cfm supply airflow, 190 cfm yokuhlunga komoya kusukela ku-'Bone Cement Air Lock", i-300 cfm yokuqoqwa kothuli, kanye no-490 cfm womoya obuyayo. 670 cfm supply air, 190 cfm exfiltration to “Gown/Ungown”. I-“Final Packaging” inomoya wokuhlinzeka nge-cfm engu-670, i-190 cfm exfiltration to 'Gown/Ungown", kanye no-480 cfm womoya obuyayo.

Manje sesinqume ukunikezwa kwegumbi elihlanzekile, ukungena ngaphakathi, ukucwiliswa, ukuphuma, nokubuya komoya. Ukugeleza komoya okubuya kwesikhala sokugcina kuzolungiswa ngesikhathi sokuqalisa ukuze kukhishwe umoya ongahleliwe.

Isinyathelo Sesikhombisa: Hlola Okuguquguqukayo Okusele

Okunye okuguquguqukayo okudingeka kuhlolwe kuhlanganisa:

Izinga lokushisa: Abasebenzi be-cleanroom bagqoka ama-smocks noma amasudi kagwaja agcwele phezu kwezingubo zabo ezivamile ukuze banciphise ukukhiqizwa kwezinhlayiya kanye nokungcoliswa okungenzeka. Ngenxa yezingubo zabo ezengeziwe, kubalulekile ukugcina izinga lokushisa eliphansi lendawo yokunethezeka kwabasebenzi. Izinga lokushisa lesikhala phakathi kuka-66°F no-70° lizohlinzeka ngezimo ezinethezekile.

Umswakamo: Ngenxa yokugeleza komoya okuphezulu kwegumbi elihlanzekile, kwakhiwa inkokhiso enkulu ye-electrostatic. Lapho usilingi nezindonga zineshaja ephezulu ye-electrostatic futhi isikhala sinomswakama ophansi ohlobene, izinhlayiya eziphuma emoyeni zizozinamathisela phezulu. Uma umswakama ohlobene nesikhala ukhuphuka, ukushaja kwe-electrostatic kuyakhishwa futhi yonke i-particle ebanjwayo ikhishwa ngesikhathi esifushane, okubangela ukuthi igumbi lokuhlanza liphume ngendlela ecacisiwe. Ukuba neshaja ephezulu ye-electrostatic kungalimaza nezinto ezibucayi zokukhishwa kwe-electrostatic. Kubalulekile ukugcina umswakama ohlobene nesikhala uphakeme ngokwanele ukuze unciphise ukunqwabelana kweshaja ye-electrostatic. I-RH noma u-45% +5% ithathwa njengezinga lomswakamo elilungile.

I-Laminarity: Izinqubo ezibucayi kakhulu zingase zidinge ukugeleza kwe-laminar ukuze kuncishiswe amathuba okungcolisa angena emoyeni phakathi kwesihlungi se-HEPA kanye nenqubo. I-IEST Standard #IEST-WG-CC006 ihlinzeka ngezidingo ze-laminarity yokugeleza komoya.

I-Electrostatic Discharge: Ngale kokunyakaziswa kwesikhala, ezinye izinqubo zizwela kakhulu ekulimaleni kokukhishwa kwe-electrostatic futhi kuyadingeka ukufaka i-flooring conductive flooring.

Amazinga Omsindo Nokudlidliza: Ezinye izinqubo ezinembayo zizwela kakhulu kumsindo nokudlidliza.

Isinyathelo Sesishiyagalombili: Thola Isakhiwo Sesistimu Yomshini

Izinombolo eziguquguqukayo zithinta ukwakheka kwesistimu ye-cleanroom: ukutholakala kwendawo, uxhaso olutholakalayo, izidingo zenqubo, ukuhlukaniswa kwenhlanzeko, ukwethembeka okudingekayo, izindleko zamandla, amakhodi wokwakha, nesimo sezulu sasendaweni. Ngokungafani namasistimu e-A/C avamile, amasistimu e-cleanroom A/C anomoya omningi kakhulu odingekayo ukuze ahlangabezane nemithwalo yokupholisa nokushisisa.

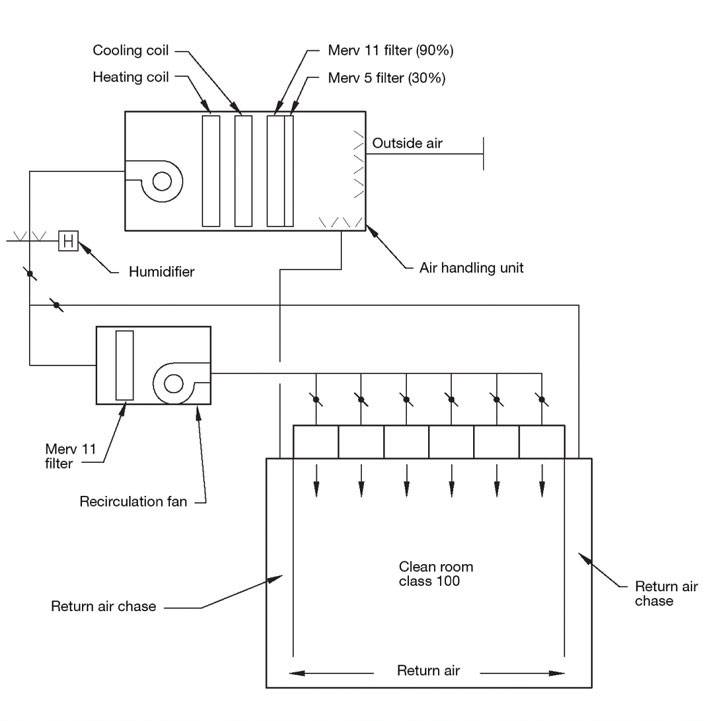

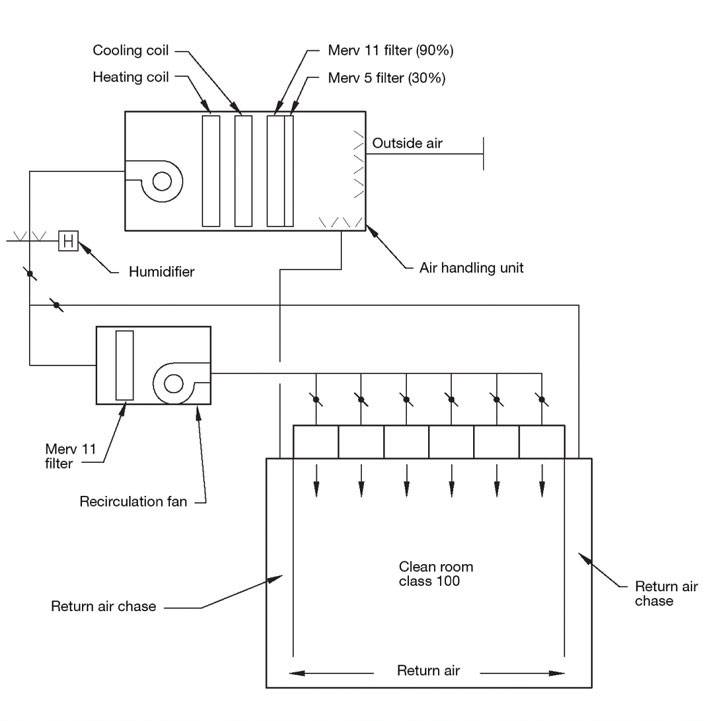

Amagumbi ahlanzekile e-Class 100,000 (ISO 8) kanye ne-ach ach Class 10,000 (ISO 7) angenza wonke umoya ungene ku-AHU. Uma ubheka uMdwebo 3, umoya obuyayo nomoya wangaphandle kuyaxutshwa, kuhlungwe, kupholiswe, kushiselwe kabusha, futhi kuswanyiswe ngaphambi kokuba kunikezwe izihlungi ze-HEPA ezigcina isilingi. Ukuze uvimbele ukuphindaphindeka kokungcola endlini ehlanzekile, umoya obuyayo uthathwa yizimbuyiselo eziphansi zodonga. Esigabeni esiphakeme esingu-10,000 (ISO 7) namagumbi ahlanzekile ahlanzekile, ukugeleza komoya kuphakeme kakhulu ukuze wonke umoya ungene ku-AHU. Uma ubheka uMdwebo 4, ingxenye encane yomoya obuyayo ibuyiselwa ku-AHU ukuze ilungiswe. Umoya osele ubuyiselwa kufeni yokujikeleza.

Okunye Okuhlukile Kumayunithi Okuphatha Umoya Endabuko

Amayunithi okuhlunga abalandeli, aziwa nangokuthi amamojula ahlanganisiwe okufutha, ayisisombululo sokuhlunga segumbi elihlanzekile elinezinzuzo ezithile ngaphezu kwezinhlelo zokubamba komoya ezivamile. Asetshenziswa kuzo zombili izindawo ezincane nezinkulu ezinesilinganiso sokuhlanzeka esiphansi njenge-ISO Class 3. Amazinga okushintsha komoya kanye nezimfuneko zokuhlanzeka zinquma inani lezihlungi zabalandeli ezidingekayo. Uphahla lwegumbi elihlanzekile le-ISO Class 8 lungase ludinge kuphela u-5-15% wokufakwa kosilingi kuyilapho i-ISO Class 3 noma igumbi lokuhlanza elihlanzekile lingadinga ukufakwa okungu-60-100%.

Isinyathelo Sesishiyagalolunye: Yenza Izibalo Zokushisisa/Ukupholisa

Lapho wenza izibalo zokushisisa/ukupholisa kwegumbi elihlanzekile, cabangela lokhu okulandelayo:

Sebenzisa izimo zezulu ezilondoloza kakhulu (idizayini yokushisisa engu-99.6%, i-0.4% ye-drybulb/median wetbulb cooling, kanye nedatha yedizayini yokupholisa isibani esimanzi esingu-0.4%).

Faka phakathi ukuhlunga ezibalweni.

Faka phakathi ukushisa okuphindaphindeka kwe-humidifier ezibalweni.

Faka phakathi inqubo yokulayisha ezibalweni.

Faka phakathi ukushisa kwefeni okuphindaphindayo kube izibalo.

Isinyathelo Seshumi: Lwela Isikhala Segumbi Lomshini

Amakamelo okuhlanza asebenza ngomshini nangogesi. Njengoba ukuhlanzeka ngezigaba kwegumbi elihlanzekile kuya ngokuya kuhlanzeka, kudingeka indawo eyengeziwe yengqalasizinda yemishini ukuze kuhlinzekwe ukwesekwa okwanele endlini ehlanzekile. Kusetshenziswa indawo yokuhlanza engu-1,000-sq-ft njengesibonelo, indawo yokuhlanza Yekilasi 100,000 (ISO 8) izodinga indawo yokusekela engu-250 kuya ku-400 sq ft, igumbi lokuhlanza le-Class 10,000 (ISO 7) lizodinga indawo yokusekela engu-250 kuya ku-750 sq, i-Class 500000000000000000000 yokusekela izodinga indawo yokusekela ehlanzekile (ISO 1), 1,000 sq ft yesikhala sokusekela, kanye negumbi lokuhlanza Lekilasi 100 (ISO 5) lizodinga u-750 kuya ku-1,500 sq ft wesikhala sokusekela.

Ukwesekwa kwangempela kwesithombe esiyisikwele kuzohluka kuye ngokugeleza komoya kwe-AHU nobunkimbinkimbi (Okulula: isihlungi, ikhoyili yokushisisa, ikhoyili epholile, nesiphephetha-moya; Inkimbinkimbi: isinqamuleli somsindo, isiphephetha-moya sokubuyisa, ingxenye yomoya wokusiza, indawo ethatha umoya wangaphandle, ingxenye yokuhlunga, ingxenye yokushisisa, ingxenye yokupholisa, i-humidifier, ifeni yokuphakela, kanye ne-plenum yokukhipha) kanye nenombolo yezinhlelo zokusekela amanzi ahlanzekile, ukudonsa umoya, i-air exhaust, i-air exhaust DI/RO amanzi). Kubalulekile ukuxhumana nesithombe esiyisikwele sendawo yemishini yemishini kumakhi wephrojekthi ekuqaleni kwenqubo yokuklama.

Imicabango yokugcina

Izindawo zokuhlanza zifana nezimoto zomjaho. Uma ziklanywe futhi zakhiwe kahle, ziyimishini yokusebenza esebenza kahle kakhulu. Uma ziklanywe kabi futhi zakhiwe, zisebenza kabi futhi azithembekile. Izindlu zokuhlanza zinezingibe eziningi ezingaba khona, futhi ukugadwa unjiniyela onokuhlangenwe nakho okubanzi kwegumbi lokuhlanza kuyanconywa kumaphrojekthi akho okuqala ambalwa egumbi elihlanzekile.

Umthombo: gotopac

Isikhathi sokuthumela: Apr-14-2020