Combined Air Handling Units

The design of HJK-E series Combined Air Handling Unit, conforms to GB/T 14294-2008 National Standards strictly and keeps deepen R&D and updates for times, established a leading advantage on Heat Recovery Technology. New generation of "U" Series Air Handling Unit, has been far beyond normal standards in many performance characteristics.

Main Features

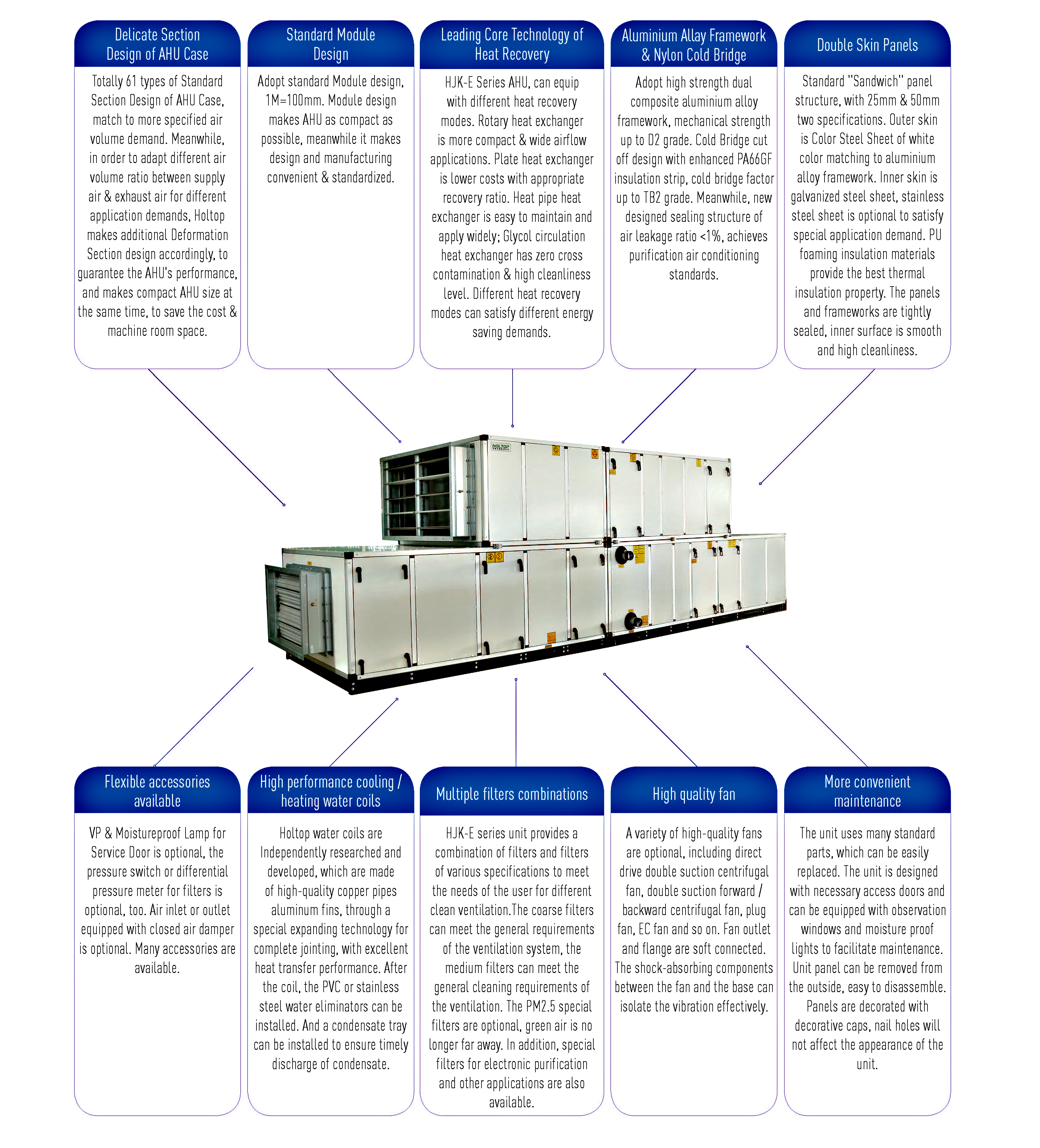

Delicate Section Design of AHU Case: Totally 61 types of Standard Section Design of AHU Case, match to more specified air volume demand. Meanwhile, in order to adapt different air volume ratios between supply air & exhaust air for different application demands, Holtop makes additional Deformation Section design accordingly, to guarantee the AHU’s performance, and makes compact AHU size at the same time, to save the cost & machine room space.

Standard Module Design: Adopt standard Module design, 1M=100mm. Module design makes AHU as compact as possible, meanwhile, it makes design and manufacturing convenient & standardized.

Leading Core Technology of Heat Recovery: HJK-E Series AHU can equip with different heat recovery modes. The rotary heat exchanger is more compact & wide airflow applications. The plate heat exchanger is at lower costs with an appropriate recovery ratio. Heat pipe heat exchanger is easy to maintain and apply widely; Glycol circulation heat exchanger has zero cross-contamination & high cleanliness level. Different heat recovery modes can satisfy different energy-saving demands.

Aluminium Allay Framework&Nylon Cold Bridge: Adopt high strength dual composite aluminum alloy framework, mechanical strength up to D2 grade. Cold Bridge cut-off design with enhanced PA66GF insulation strip, cold bridge factor up to TB2 grade. Meanwhile, new designed sealing structure of air leakage ratio <1%, achieves purification air conditioning standards.

Double Skin Panels: Standard “Sandwich” panel structure, with 25mm & 50mm two specifications. The outer skin is colour Steel Sheet of white colour matching to aluminum alloy framework. Inner skin is galvanized steel sheet, stainless steel sheet is optional to satisfy special application demand. PU foaming insulation materials provide the best thermal insulation property. The panels and frameworks are tightly sealed, the inner surface is smooth and has high cleanliness.

Flexible accessories available: VP & Moistureproof Lamp for Service Door is optional, the pressure switch or differential pressure meter for filters is optional, too. Air inlet or outlet equipped with closed air damper is optional. Many accessories are available.

High-performance cooling/heating water coils: Holtop water coils are independently researched and developed, which are made of high-quality copper pipes aluminum fins, through a special expanding technology for complete jointing, with excellent heat transfer performance. After the coil, the PVC or stainless steel water eliminators can be installed. And a condensate tray can be installed to ensure timely discharge of condensate.

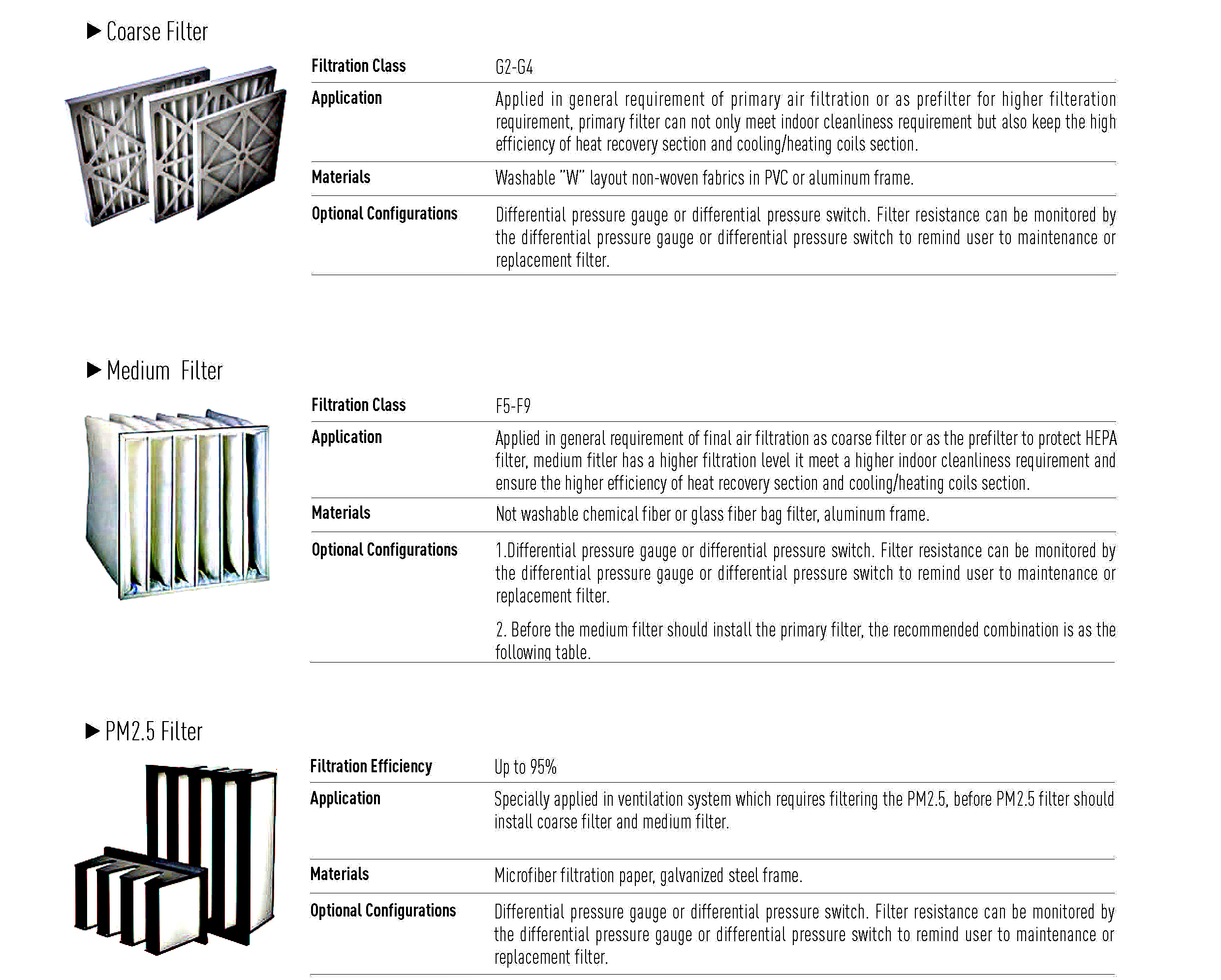

Multiple filters combinations: HJK-E series unit provides a combination of filters and filters of various specifications to meet the needs of the user for different clean ventilation. The coarse filters can meet the general requirements of the ventilation system, the medium filters can meet the general cleaning requirements of the ventilation. The PM2.5 special filters are optional, green air is no longer far away. In addition, special filters for electronic purification and other applications are also available.

High-quality fan: A variety of high-quality fans are optional, including direct drive double suction centrifugal fan, double suction forward /backward centrifugal fan, plug fan, EC fan and so on. The fan outlet and flange are soft connected. The shock-absorbing components between the fan and the base can isolate the vibration effectively.

More convenient maintenance: The unit uses many standard parts, which can be easily The unit is designed with necessary access doors and can be equipped with observation windows and moisture-proof lights to facilitate maintenance. Unit panel can be removed from the outside, easy to disassemble. Panels are decorated with decorative caps, nail holes will not affect the appearance of the unit.

AHU Functional Section- Filter Section

AHU Functional Section - Heat Exchanger Section

Rotary Heat Exchanger Section

Working Principle: The rotary heat exchanger is constructed by alveolate heat wheel, casing, driving system and sealing parts. The exhaust air and fresh air go through half of the wheel separately. In winter exhaust air heat is absorbed by fresh air while in summer fresh air heat took away by exhaust air, in a similar way, moisture exchange between fresh air and exhaust air.

Plate Fin / Plate Heat Exchanger Section

Working Principle: Air to air plate heat exchanger is made of aluminum foils or special ER paper with totally separated and sealed airflow channels. When two air streams (fresh air and exhaust air) passing through two sides of the plate with temperature or moisture difference in crossflow way or counterflow way, heat or moisture will be exchanged.

Heat Pipe Heat Exchanger

Working Principle: When heating one end of the heat pipe, the liquid inside this end evaporates, the stream flows to the other end under pressure difference. Steam will condense and release heat in the condensing end. Heat transfers from high temperature to low temperature finished, condensate flows back to the evaporating end. In the same way, the liquid inside the heat pipe evaporates and condenses circularly, so, heat is transferred from high temperature to low temperature constantly.

Liquid Circulation Heat Exchanger

Working Principle: Liquid circulation heat exchanger is liquid to air heat exchanger, heat exchangers installed in both fresh airside and exhaust airside, the pump between the 2 heat exchangers make the liquid circulate than the heat in the liquid preheat or precool the fresh air. Normally the liquid is water but in order to decrease the freezing point, moderate ethylene glycol will be added into the water according to a reasonable percentage.

AHU Functional Section -Fan Section

For HJK-E series AHU, there are different types of fans for options, such as direct-driven centrifugal fan, belt-driven DIDW forward / backward centrifugal fan, plug fan and EC fan. They are of high quality, superior performance and outstanding durability.

AHU Functional Section - Cooling and Heating Coils

Cooling and heating coils are made of red copper tube and hydrophilic aluminum fins, with the special processing technology to fix the copper tube and aluminum fins together, the technology significantly improves the heat transfer efficiency and at the same time to reduce the air resistance. An optional PVC or aluminum alloy water eliminator can be installed after the coils to avoid the condensate water being blown to supply air. The cooling and heating coils section is designed with a condensate water pan to ensure the fast removal of condensate water, optional stainless steel water pan is available under special circumstances.

AHU Functional Section -Humidifier

We are able to produce wet film humidification, high-pressure spray humidification, dry steam humidification, electrode humidification, electric heating humidification and other humidification functional sections. Users can choose different types of humidification sections according to different requirements like humidification efficiency and humidification accuracy.