Holtop Modular Air Cooled Chiller With Heat Pump

Product Overview:

Holtop Air Cooled Modular Chiller are our latest product based on over twenty years of regular research & development, technology accumulation and manufacturing experience which helped us to develop chillers with stable & reliable performance, greatly improved evaporator & condenser heat transfer efficiency. In this way it's the best choice to save energy, protect environment and achieve comfortable air conditioning system.

Holtop Air Cooled Modular Chiller use air as a cooling source and refrigerant water as a cooling medium for central air conditioning units. This product series have different type of specifications cooling capacity ranging from 65 to 130 kW and heating capacity ranging from 71 to 141 kW. It can meet the demand at different loads with FCU and Combined type AHU's etc. Terminal equipment consists of various central air-conditioning systems which can meet the building cooling requirements. Units have advantages of compact structure, high efficiency, low noise and long life, convenient operation etc. It can provide all kinds of central air conditioning system and processes with chilled water. Holtop Modular Air Cooled Chiller can widely used in hotels, hospitals, shopping malls, office buildings, cinemas, metal industry, oil & chemical industry, manufacturing industry, electronics industry, electric power stations etc.

Product Description

Product Features

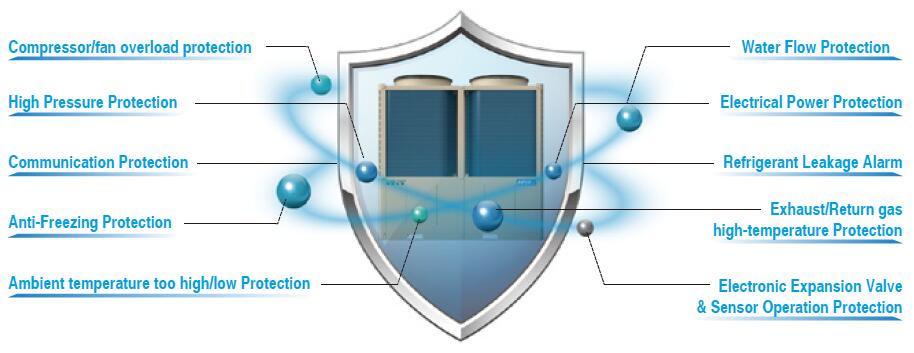

1. Integrated Protection:Designing more than 10 safety protection functions, which can ensure chiller unit and the system operation in all-round protection. The unit can be controlled through a multi-variable monitoring system to ensure the unit with stable and efficient operation.

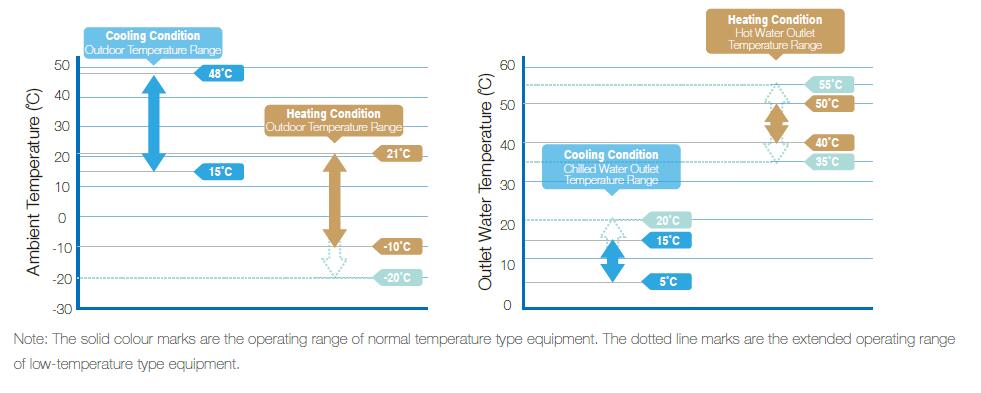

2. Wide Temperature Range of Application, Worry-free of Operation:Chiller unit is suitable for operation in a wide outdoor temperature range, from -20°C~48°C.

3. Chiller Unit Operation When Has Fault: A single unit is designed with multiple compressors. When one of the compressors fails, the rest of the compressors in the system can still operate normally without affecting the operation of the whole system.

4. Modular Combination: The chiller adopts modular combination design and does not need to set the master or sub-master unit. Each combination is able to connect a maximum of 16 units, even they are made of different models, to meet the variable demands of different buildings.

5. Step Starting: Starting all units in steps, in order to lower the starting current, reduce the shock to power grid, and avoid affecting the security of other electrical equipment.

6. Flexible Application: Investment: Add extra units into combination at any time, convenient for multiple stages of investment. Transportation: The volume of each unit is compact, can be transported individually, does not need a crane at the project site, can save transportation cost. Installation: Does not need machine room or cooled water system, only somewhere with good ventilation. The water pipes are designed on side of the unit, which can be easy for chilled water connection and save installation space. System: At the water circulating system, besides the standard use of the constant flow system, it is optional to use the primary pump with a variable flow system, and the variable speed control cabinet is optional to select.

7. Smart Defrosting System: By sensing with the multi-variables system to have accurate judgement on the situation of frosting, the chiller itself can be able to choose the best time to enter or exit defrosting, to avoid insufficient defrosting or over defrosting. In a duplex system, the units can achieve alternate defrosting. When heating under extreme low-temperature conditions, setting manual defrosting for better performance.

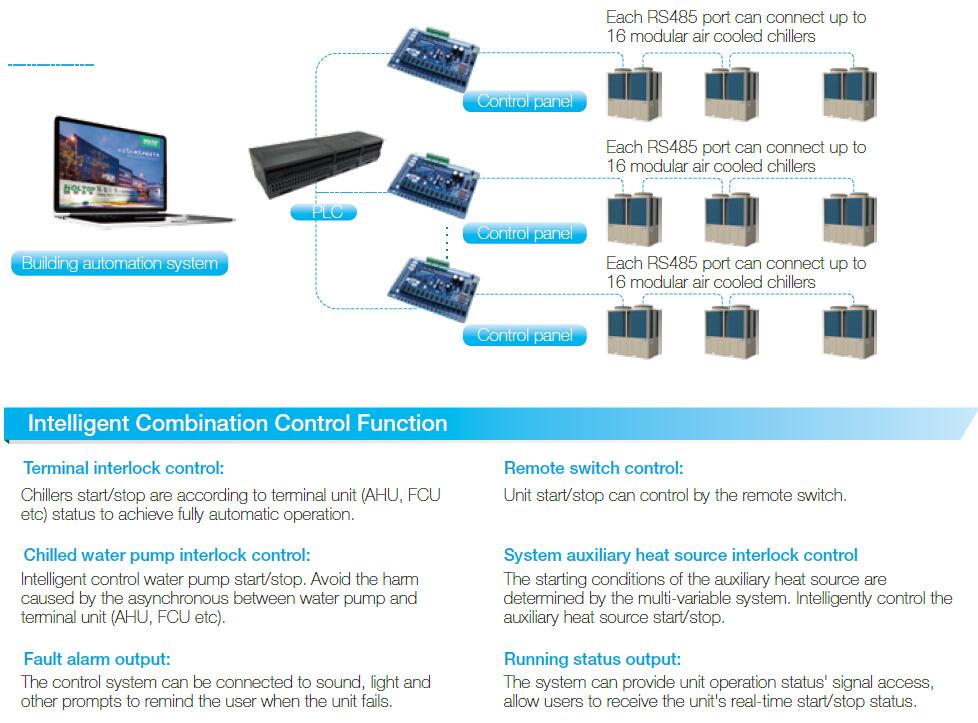

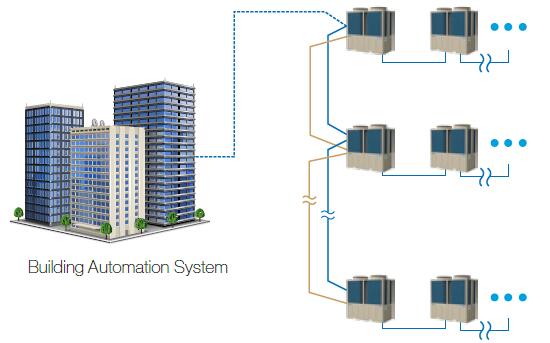

8. Intelligent PLC Control System: The PLC control system combines the simplicity and convenience of the wired control system and the advantages of the centralized group control system to achieve chiller group centralized control. One PLC control system can manage 1 to 8 groups. Each group can control 1 to 16 pieces of modular chillers. The system can control up to 128 modular chillers. The control system also delivers various features such as group mode switching, temperature adjustment, on/off control, etc to adopt numerous applications.

9. Free Access to Building Automation System: Standard RS485 building communication interface comes with open access to standard ModBus communication protocol. The device can be easily connected to the building control system (BAS) for centralized control, easy to achieve intelligent control, avoid unnecessary energy waste, and save air-conditioning operating costs.

Product Parameter

| Product Parameter | |||||

| Model/Specification | HFW-65HA1 | HFW-65HA1-L | HFW-130HA 1 |

HFW-130HA1-L | |

| Normal temperature type | Low-temperature type | Normal temperature type | Low-temperature type | ||

| Nominal cooling capacity(KW) | 65 | 63 | 130 | 130 | |

| Nominal heating capacity(KW) | 71 | 71 | 142 | 141 | |

| Cooling | Rated total input power(KW) | 19.5 | 18.7 | 39 | 37.7 |

| Heating | Rated total input power(KW) | 21 | 19.5 | 42 | 38.8 |

| Nominal low-temperature cooling capacity(KW) | / | 52 | / | 100 | |

| Total nominal low-temperature heating input power(KW) | / | 18.6 | / | 37 | |

| Voltage | 380V/3N~/50Hz | ||||

| Refrigerant | R410A | ||||

| Throttle parts | Electronic expansion valve | ||||

| Compressor | Type | Hermetic scroll | |||

| Qty | 2 | ||||

| Fan | Type | Axial low noise fan | |||

| Power(kw) | 0.9*2 | 1.5*2 | |||

| Airside heat exchanger | Airflow(m³/h) | 14000*2 | 19500*2 | ||

| Type | High-efficient finned heat exchange | ||||

| Waterside heat exchanger | Nominal water flow(m³/h) | 11.5 | 11.5 | 22.5 | 22.5 |

| Type | High-efficient shell&tube heat exchanger | ||||

| Water pressure drop(kPa) | 30 | 40 | |||

| Water inlet/outlet connection pipe | DN50 | DN65 | |||

| Dimension W*H*D (mm) | 1810*960*2350 | 2011*1100*2300 | |||

| Net weight(kg) | 580 | 600 | 1000 | 1050 | |