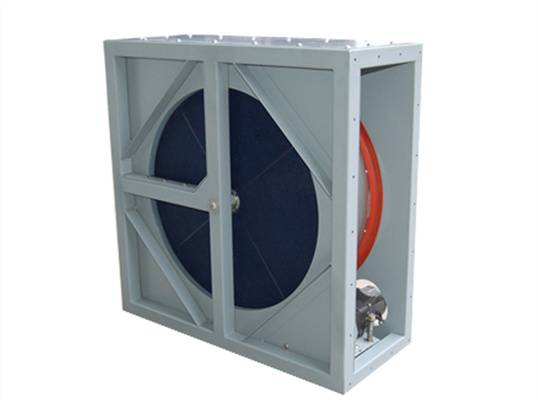

Roterande värmeväxlare

Huvudfunktioner hos roterande värmeväxlare:

1. Hög effektivitet av förnuftig eller entalpi värmeåtervinning

2. Dubbelt labyrintätningssystem garanterar minimalt luftläckage.

3. Självrengöringsarbete förlänger servicecykeln och minskar underhållskostnaderna.

4. Dubbelspolningssektor minimerar överföring från frånluft till tilluftström.

5. Livssmord lager behöver inget underhåll vid normal användning.

6. Inre ekrar används för att mekaniskt binda rotorns lameller för att förstärka hjulet.

7. Färdigt utbud av rotordiameter från 500 mm till 5000 mm, rotor kan skäras i 1 st till 24 st för enkel transport, olika typer av huskonstruktion finns också.

8. Valprogramvara för bekvämt val.

Arbetsprincip:

Roterande värmeväxlare består av alveolat värmehjul, hölje, drivsystem och tätningsdelar. Frånluften och uteluften passerar separat genom hälften av hjulet, när hjulet roterar växlas värme och fukt mellan avgas och utomhusluft. Effektiviteten för energiåtervinning är upp till 70% till 90%.

Hjulmaterial:

Det förnuftiga värmehjulet är tillverkat av aluminiumfolier med en tjocklek på 0,05 mm. Och det totala värmehjulet är tillverkat av aluminiumfolier belagda med 3A molekylsikt med 0,04 mm tjocklek.

Tillämpningar:

Roterande värmeväxlare kan byggas in i luftbehandlingsenheten (AHU) som en viktig del av värmeåtervinningssektionen. Vanligtvis är sidopanelen på växelhöljet onödig, förutom att bypass har ställts in i AHU.

Den kan också installeras i ventilationssystemets kanaler som en huvuddel i värmeåtervinningsdelen, ansluten med fläns. I det här fallet är sidopanelen på växlaren nödvändig för att förhindra läckage.