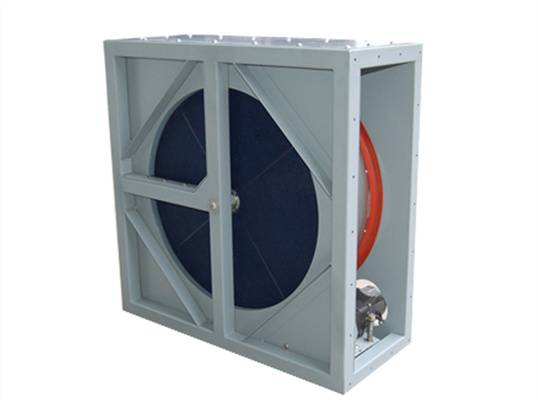

Schimbătoare de căldură rotative

Principalele caracteristici ale schimbătorului de căldură rotativ:

1. Eficiență ridicată a recuperării de căldură sensibilă sau entalpică

2. Sistemul de etanșare dublu labirint asigură scurgeri minime de aer.

3. Eforturile de autocurățare prelungesc ciclul de service, reducând costurile de întreținere.

4. Sectorul de dublă purjare minimizează transferul de aer evacuat în fluxul de aer alimentat.

5. Rulmentul lubrifiat pe tot parcursul vieții nu necesită întreținere în condiții normale de utilizare.

6. Spițele interioare sunt utilizate pentru a lega mecanic laminările rotorului pentru a întări roata.

7. Gama completă a diametrului rotorului de la 500 mm la 5000 mm, rotorul poate fi tăiat în 1 buc până la 24 buc pentru transport ușor, sunt disponibile și diferite tipuri de construcții de carcase.

8. Software de selecție pentru o selecție convenabilă.

Principiul de funcționare:

Schimbătorul de căldură rotativ este compus din roată de căldură alveolată, carcasă, sistem de acționare și piese de etanșare. Aerul evacuat și aerul exterior trec prin jumătate din roată separat, când roata se rotește, căldura și umiditatea sunt schimbate între aerul evacuat și aerul exterior. Eficiența recuperării energiei este de până la 70% până la 90%.

Materiale roți:

Roata de căldură sensibilă este realizată din folii de aluminiu cu grosimea de 0,05 mm. Și roata de căldură totală este realizată din folii de aluminiu acoperite cu o sită moleculară 3A de 0,04 mm grosime.

Aplicații:

Schimbătorul de căldură rotativ poate fi încorporat în unitatea de tratare a aerului (AHU) ca parte principală a secțiunii de recuperare a căldurii. De obicei, panoul lateral al carcasei schimbătorului nu este necesar, cu excepția faptului că bypass-ul a fost setat în AHU.

Poate fi instalat și în canalele sistemului de ventilație ca parte principală a secțiunii de recuperare a căldurii, conectată prin flanșă. În acest caz, panoul lateral al schimbătorului este necesar pentru a preveni scurgerile.