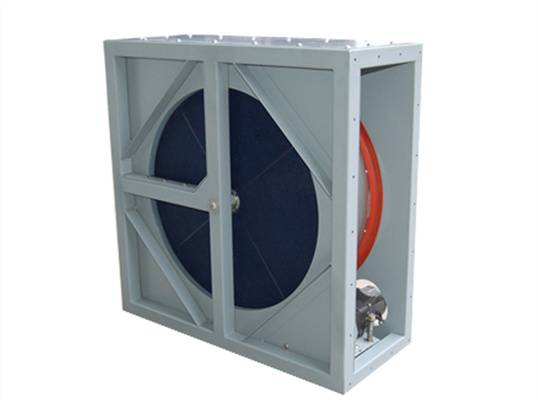

Roterende hitte-uitruilers

Belangrikste kenmerke van roterende hitteruiler:

1. Hoë doeltreffendheid van sinvolle of entalpiese hitteherwinning

2. Dubbele labirint seëlstelsel verseker minimale luglekkasie.

3. Selfsuiweringspogings verleng die dienssiklus en verminder die onderhoudskoste.

4. Die sektor vir dubbele suiwering verminder die oordrag van afvoerlug na die toevoerlugstroom.

5. Lewenslange gesmeerde laer benodig geen onderhoud onder normale gebruik nie.

6. Binne-speke word gebruik om die rotorlaminasies meganies te bind om die wiel te versterk.

7. Voltooide reeks rotordiameter van 500mm tot 5000mm, die rotor kan in 1 tot 24 stuks gesny word vir maklike vervoer, verskillende soorte behuisingskonstruksie is ook beskikbaar.

8. Seleksiesagteware vir maklike keuse.

Werkbeginsel:

Roterende hitteruiler is saamgestel uit alveole hittewiel, koffer, aandryfstelsel en seëlonderdele. Die uitlaat- en buitelug gaan afsonderlik deur die helfte van die wiel, wanneer die wiel draai, word die hitte en vog tussen die uitlaat- en buitelug geruil. Die energieherwinningsdoeltreffendheid is tot 70% tot 90%.

Wielmateriaal:

Die sinvolle hittewiel word vervaardig deur aluminiumfoelies met 'n dikte van 0,05 mm. En die totale hittewiel word vervaardig deur aluminiumfoelies bedek met 3A molekulêre sif van 0,04 mm dikte.

Aansoeke:

Rotary warmtewisselaar kan 'n ingeboude lugbehandelingseenheid (AHU) vorm as 'n hoofdeel van die afdeling vir hitteherwinning. Gewoonlik is die sypaneel van die wisselaaromhulsel onnodig, behalwe dat die omleiding in AHU ingestel is.

Dit kan ook in die kanale van die ventilasiestelsel geïnstalleer word as 'n hoofdeel van die hitteherwinningsafdeling, verbind deur 'n flens. In hierdie geval is die sypaneel van die wisselaar nodig om lekkasie te voorkom.