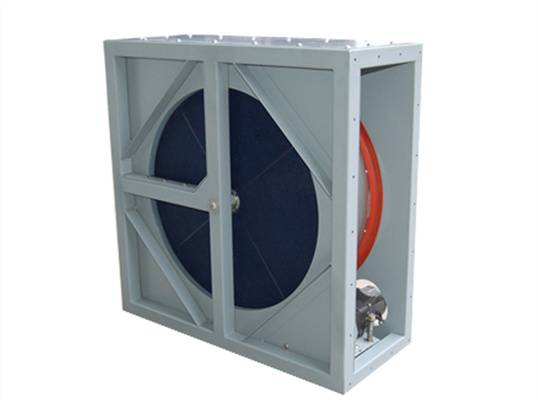

회전식 열교환 기

회전식 열교환 기의 주요 특징 :

1. 현명하거나 엔탈피 열회수 고효율

2. 이중 래비 린스 씰링 시스템은 공기 누출을 최소화합니다.

3. 자체 청소 노력은 서비스주기를 연장하여 유지 보수 비용을 줄입니다.

4. 이중 퍼지 섹터는 배기에서 공급 공기 흐름으로의 캐리 오버를 최소화합니다.

5. 수명 윤활 베어링은 정상적인 사용시 유지 보수가 필요하지 않습니다.

6. 내부 스포크는 바퀴를 강화하기 위해 로터의 라미네이션을 기계적으로 접착하는 데 사용됩니다.

7. 500mm에서 5000mm까지 로터 직경의 완성 된 범위, 로터는 쉬운 수송을 위해 1pc에서 24pcs로 절단 될 수 있습니다, 다양한 유형의 주택 건설도 가능합니다.

8. 편리한 선택을위한 선택 소프트웨어.

작동 원리:

회전식 열교환 기는 폐포 형 히트 휠, 케이스, 구동 시스템 및 씰링 부품으로 구성됩니다. 배기와 실외 공기는 휠의 절반을 별도로 통과하며 휠이 회전하면 열과 습기가 배기와 실외 공기 사이에서 교환됩니다. 에너지 회수 효율은 최대 70 % ~ 90 %입니다.

휠 재료 :

현열 휠은 0.05mm 두께의 알루미늄 호일로 만들어집니다. 그리고 전체 히트 휠은 0.04mm 두께의 3A 분 자체로 코팅 된 알루미늄 호일로 만들어집니다.

신청 :

회전식 열교환 기는 열 회수 섹션의 주요 부분으로 공기 처리 장치 (AHU)에 내장 될 수 있습니다. 일반적으로 교환기 케이스의 측면 패널은 AHU에 바이 패스가 설정된 경우를 제외하고는 불필요합니다.

플랜지로 연결된 열회수 섹션의 주요 부분으로 환기 시스템의 덕트에 설치할 수도 있습니다. 이 경우 누수 방지를 위해 교환기의 측면 패널이 필요합니다.