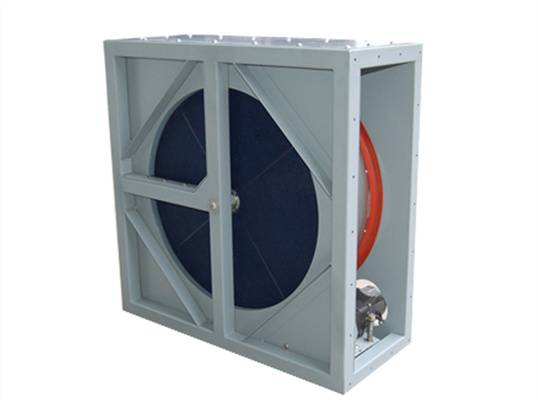

Roterende varmevekslere

Hovedtrekk ved roterende varmeveksler:

1. Høy effektivitet av fornuftig eller entalpi varmegjenvinning

2. Dobbelt labyrintforseglingssystem sikrer minimal luftlekkasje.

3. Selvrensende arbeid forlenger servicesyklusen, og reduserer vedlikeholdskostnadene.

4. Dobbelt skyllesektor minimerer overføring fra avtrekksluft til tilluftstrøm.

5. Livssmurt lager krever ikke vedlikehold under normal bruk.

6. Innvendige eiker brukes til å binde rotorens laminasjoner mekanisk for å forsterke hjulet.

7. Fullført utvalg av rotordiameter fra 500 mm til 5000 mm, rotor kan kuttes i 1 stk til 24 stk for enkel transport, forskjellige typer boligkonstruksjon er også tilgjengelig.

8. Valgprogramvare for praktisk valg.

Arbeidsprinsipp:

Roterende varmeveksler består av alveolat varmehjul, koffert, drivsystem og tetningsdeler. Eksosen og uteluften passerer separat gjennom halvparten av hjulet, når hjulet roterer, blir varmen og fuktigheten utvekslet mellom eksosen og uteluften. Effektiviteten for energigjenvinning er opptil 70% til 90%.

Hjulmaterialer:

Det fornuftige varmehjulet er laget av aluminiumsfolier med en tykkelse på 0,05 mm. Og det totale varmehjulet er laget av aluminiumsfolier belagt med 3A molekylsikt med en tykkelse på 0,04 mm.

Applikasjoner:

Roterende varmeveksler kan innebygd luftbehandlingsenhet (AHU) som en hoveddel av varmegjenvinningsdelen. Vanligvis er sidepanel på vekslerhylsen unødvendig, bortsett fra at bypass er satt i AHU.

Den kan også installeres i kanalene til ventilasjonssystemet som en hoveddel av varmegjenvinningsdelen, forbundet med flens. I dette tilfellet er sidepanelet på veksleren nødvendig for å forhindre lekkasje.