What is Fan Filter Unit?

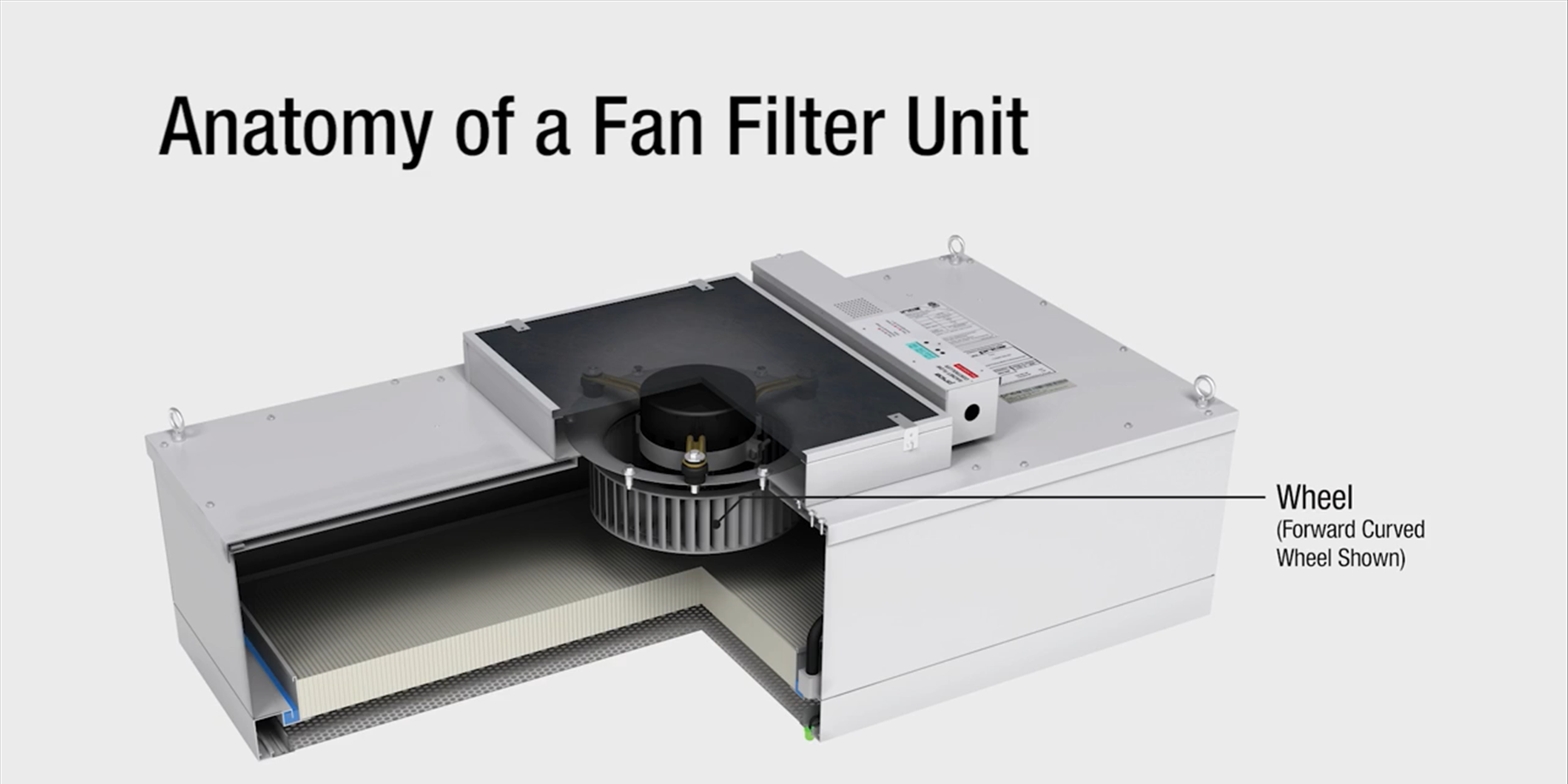

A fan filter unit or FFU is essential a laminar flow diffuser with an integrated fan and motor. The fan and motor are there to overcome the static pressure of the internally mounted HEPA or ULPA filter. This is beneficial in retrofit applications where the existing fan power from the air handler is insufficient to overcome the filter pressure drop. FFU are ideally suited for new construction where high air change rates and ultra clean environments are required. This includes applications such as hospital pharmacies, pharmaceutical compounding areas and micro electronics or other sensitive manufacturing facilities. FFU can also be used to quickly and easily upgrade the ISO classification of rooms simply by adding fan filter units to the ceiling. It is common for ISO plus 1 to 5 clean rooms for the entire ceiling to be covered in fan filter units by using FFU instead of a central air handler to provide the required air changes. The size of the air handler can be greatly reduced. Additionally with a large array of FFU the failure of one FFU does not compromise the functionality of the entire system.

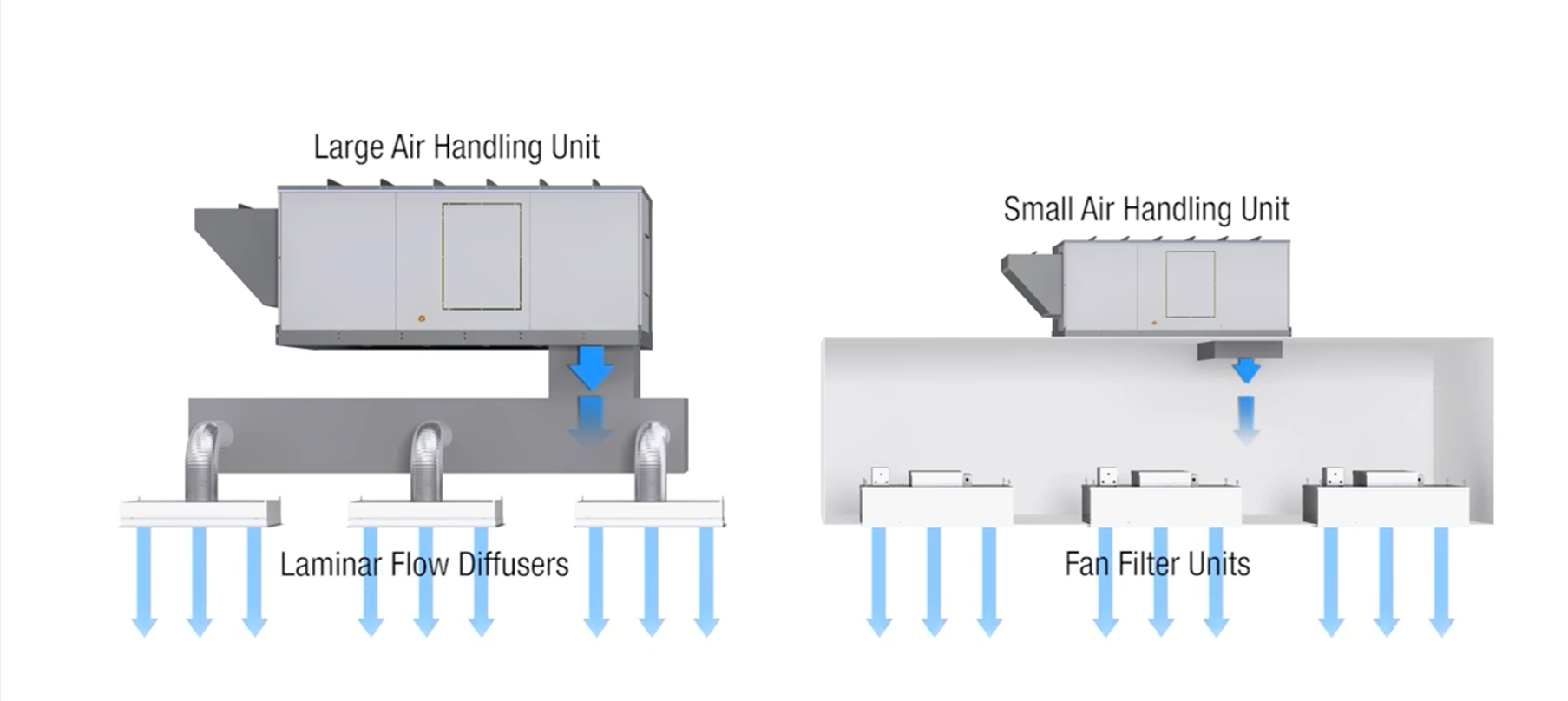

System Design:

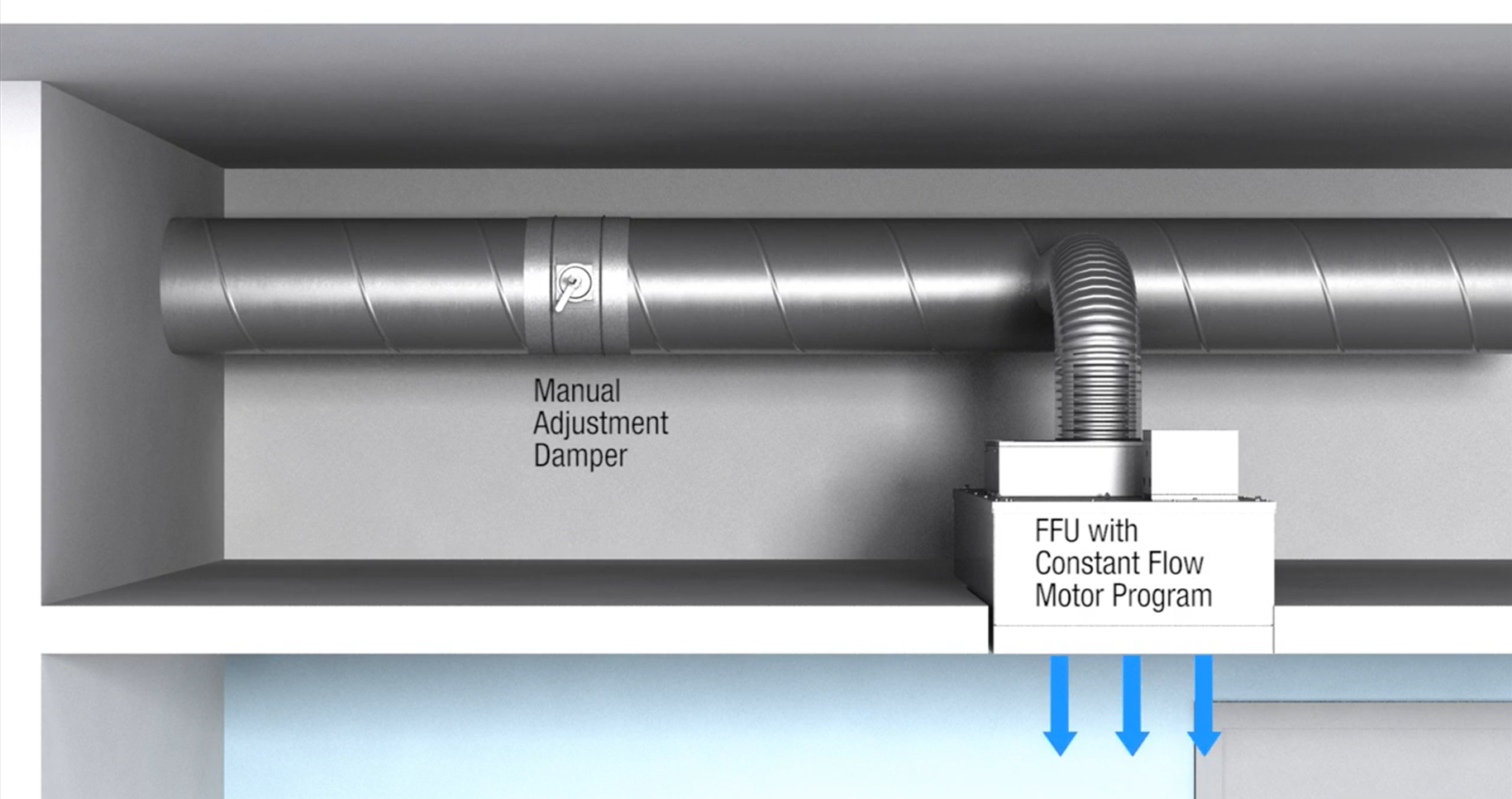

A typical clean room system design is to use a negative pressure common plenum where the FFU draw surrounding air from the common returns, and is mixed with the condition make up air from the air handling unit. One major advantage of a negative pressure common plenum FFU system is that it eliminates the risks of contaminants migrating from the ceiling plenum into the clean space below. This allows for a less expensive and complex ceiling system to be used. Alternatively for installations with fewer units.

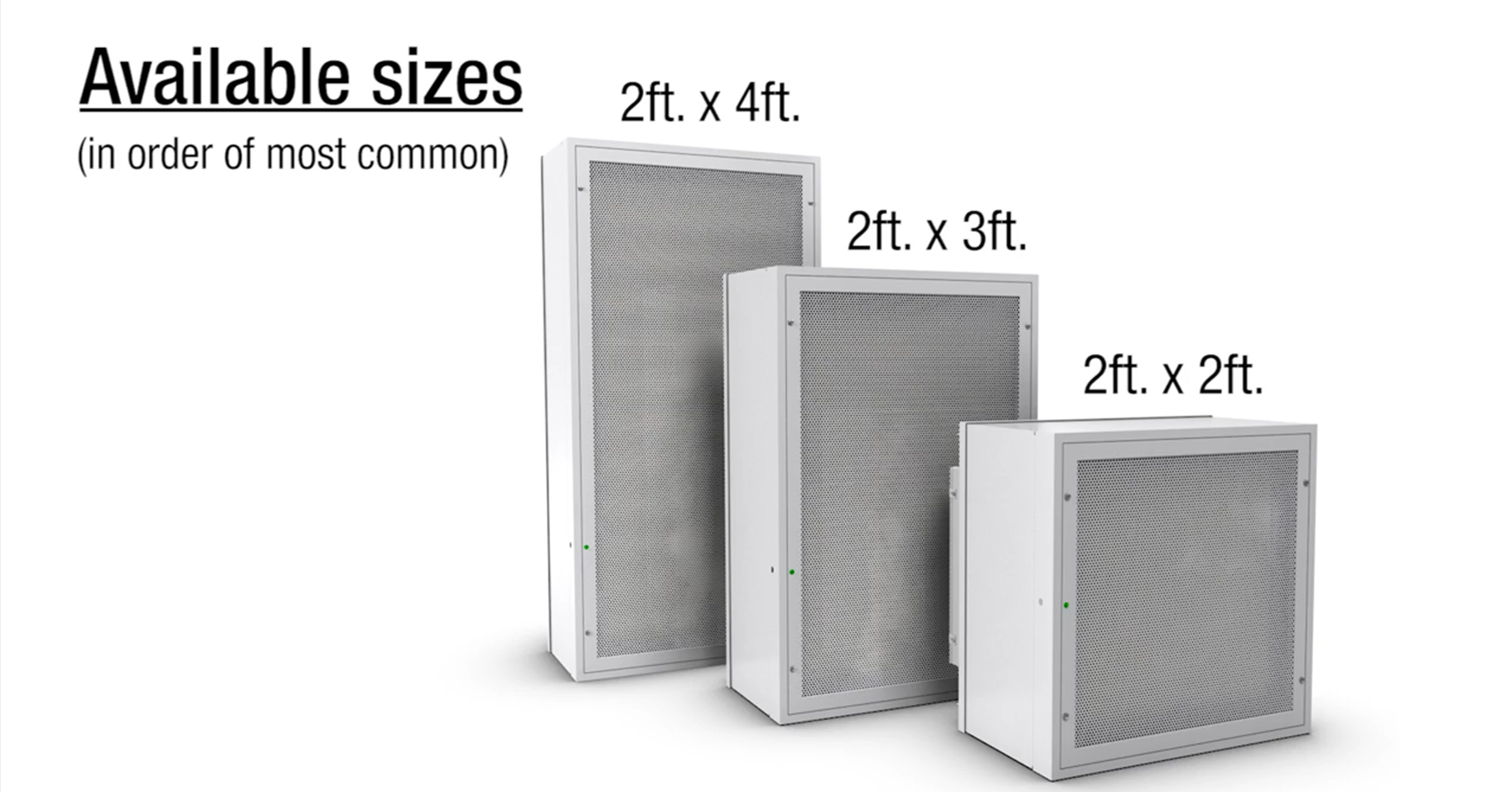

Standard Size:

The FFU can be directly ducted from the air handler or terminal device. This is ideal for retrofit applications where the space is being upgraded from non-filter laminars to ducted FFU. FFU are typically available in three sizes, 2ft x 2 ft, 2ft x 3 ft, 2 ft x 4ft and are designed to fit into a standard suspended ceiling grid. FFU are typically sized for 90 to 100 FPM. For most popular size of 2ft x 2 ft this equates to 480 CFM for a room side replaceable filter model. Filter changes are a necessary part of regular maintenance.

Filter Styles:

There are two different FFU styles that facilitate filter changes in different ways. Room side replaceable filter models allow access to the filter from the room side without compromising the integrity of the ceiling system. Room side removable units feature an integrated knife edge that engages into the filter gel seal to ensure a leak free connection. Bench top replaceable units must be removed from the ceiling in order to replace the filter. Bench top replaceable filters have 25% more filter area which allows for higher air flow rates.

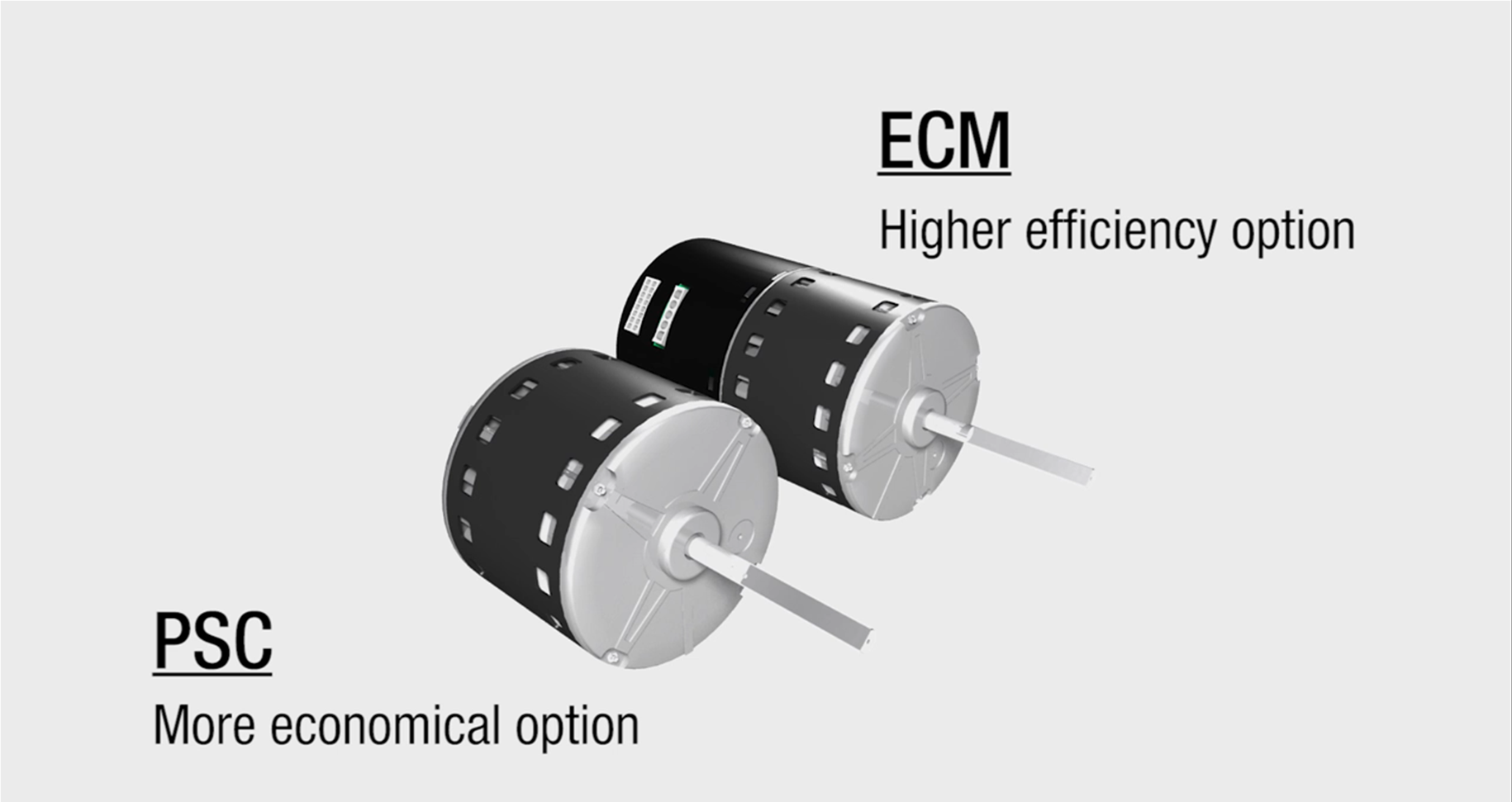

Motor Options:

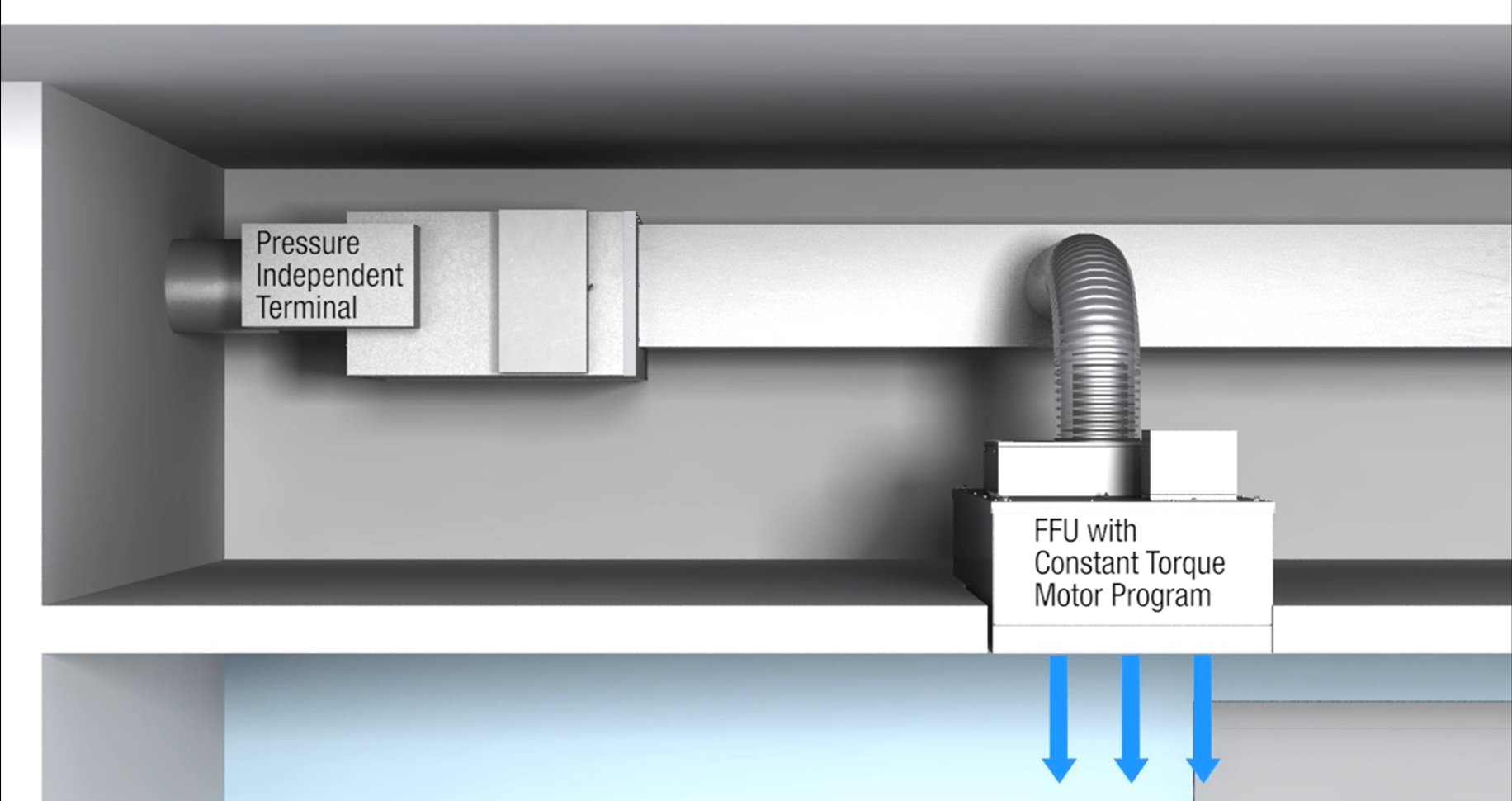

Another option to look at when selecting a fan unit is a type of motor used. PSC or AC induction type motors are the more economical option. ECM or brushless DC motors are the higher efficiency option with onboard micro processors that optimize motor performance and allow for motor programming. When using an ECM there are two available motor programs. The first is constant flow. The constant flow of motor program maintains the airflow through the fan filter unit independent of the static pressure as the filter loads. This is ideal for negative pressure common plenum designs. The second motor program is constant torque. The constant torque motor program maintains that torque or the rotational force of the motor independent of the static pressure as the filter loads. To maintain constant air flow through the fan filter unit with a constant torque program, an upstream pressure independent terminal or venturi valve is required. An FFU with a constant flow program should not be directly ducted to an upstream pressure independent terminal device, as this causes both smart devices to fight for control and can lead to airflow oscillation and poor performance.

Wheels Options:

In addition to motor options there are also two wheel options. Forward curved wheels are the standard option and are compatible with the EC motor and constant flow program. Backward curved wheels although not compatible with the constant flow motor program are a more energy-efficient option.

FFU's have steadily increased in popularity due to their energy efficient design and reduced risk of downtime as a result of the decentralized air handling system. The modular design of FFU systems allows for quick and easy changes to ISO classifications of cleanrooms. FFU's have many useful features and options which allow for complete customization of the system and a full range of featurerich control options allowing for quick Start up and commissioning, and full control and monitoring of the system during operation.

Post time: Dec-17-2020