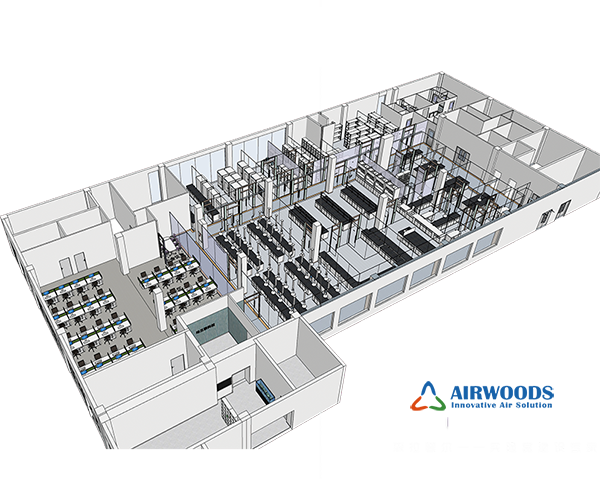

The ventilation system is one of the important factors in the Cleanroom design and construction process. The system installation process has direct impact on the laboratory environment and cleanroom equipments’ operation and maintenance.

Excessive negative pressure, air leakage in the bio-safety cabinet and excessive laboratory noise are common deficiency in the ventilation system. These problems caused serious physical and psychological harm to laboratory staffs and other personals work around the laboratory. A qualified cleanroom ventilation system has good ventilation result, low noises, easy operation, energy saving, also require excellent control of indoor pressure, temperature and humidity to maintain human comfort.

The correct installation of ventilation ducts links to effective operation and energy saving of the ventilation system. Today we will take a look at some of the problems we need to avoid when installing ventilation ducts.

01 The air ducts’ internal waste are not cleaned up or removed before installation

Before the installation of air duct, the internal and external waste should be removed. Clean up and sanitize all the air ducts. After construction, the duct should be sealed in time. If the internal waster are not removed, the air resistance will be increased, and causing clogged filter and pipeline.

02 Air leak detection are not done properly according to the regulations

The air leak detection is the important inspection to test the ventilation system construction quality. The inspection process should follow the regulation and specifications. Skipping the light and air leak detection may cause large amount of air leak. Leading projects failed to pass the requirement and increase unnecessary rework and waste. Causing the construction cost increase.

03 The installation position of the air valve is not convenient for operation and maintenance

All types of dampers should be installed in locations that are convenient for operation and maintenance, and inspection ports should be set up in the suspended ceiling or on the wall.

04 The large distance gap between duct supports and hangers

The large gap between the duct supports and hangers may causing the deformation. The improper use of the expansion bolts may cause the ducting weight exceed the lifting points’ load-bearing capacity and even cause the duct to fall resulting safety hazard.

05 Air leaks from flange connection when using combined air duct system

If the flange connection does not install properly and fail the air leak detection, it will cause excessive air volume loss and causing energy waste.

06 The flexible short pipe and rectangular short pipe are twisted during installation

Distortion of the short tube can easily cause quality problems and affect the appearance. Special attention should be paid when installing.

07 The flexible short pipe of the smoke prevention system is made of flammable materials

The material of the flexible short pipe of the smoke prevention and exhaust system must be non-combustible materials, and flexible materials that are anticorrosive, moisture-proof, airtight, and not easy to mold should be selected. The air-conditioning system should take measures to prevent condensation; the air-conditioning purification system should also be made of materials with smooth inner walls and not easy to generate dust.

08 No anti-swing support for the air duct system

In the installation of laboratory ventilation ducts, when the length of the horizontally suspended air ducts exceeds 20m, we should set up a stable point to prevent swing. Missing stable points may cause air duct moves and vibrates.

Airwoods has over 17 years of experience in providing comprehensive solutions to treat various BAQ (building air quality) problems. We also provides professional cleanroom enclosure solutions to customers and implements all-round and integrated services. Including demand analysis, scheme design, quotation, production order, delivery, construction guidance, and daily use maintenance and other services. It is a professional cleanroom enclosure system service provider.

Post time: Oct-21-2020