Why Get Help Building A Cleanroom?

Cleanroom construction, much like building a new facility, requires a myriad of workers, parts, materials, and design considerations. Sourcing components and supervising construction for a new facility is not something you’d ever take on by yourself. Why would building a cleanroom be any different?

How Much Does a Cleanroom Cost?

Cleanrooms are like race cars. When properly designed and built, they are highly efficient performance machines. When poorly designed and built, they operate poorly and are unreliable.

A short-hand cleanroom cost estimate should leave a buyer weary, as should an estimate far below market price. Estimating the true cost of a cleanroom requires preliminary engineering and computing. Imagine a wedding planner providing the cost of a wedding without considering the number of guests, the cost of the venue, or accommodations for food and music?

What is the Greatest Cleanroom Cost Factor?

The cost of cleanroom varies dramatically based on size, application, and compliance requirements. Generally, cleaner spaces require more air changes per hour (ACH). Higher volumes of air require expanded HVAC and design considerations, thus expanding cost. The ambient temperature and humidity of the space also have cost implications. Beyond size and cleanliness, accommodation for critical applications also expands cost. Sterile compounding or hazardous drugs require acute controls for room pressurization. These applications require multiple cleanroom segmentations with cascading room pressure. In summary, gauging the cost of a cleanroom is nearly impossible without determining its size and compliance requirements.

How Does the Level of ISO Classification Impact Build and Operating Costs?

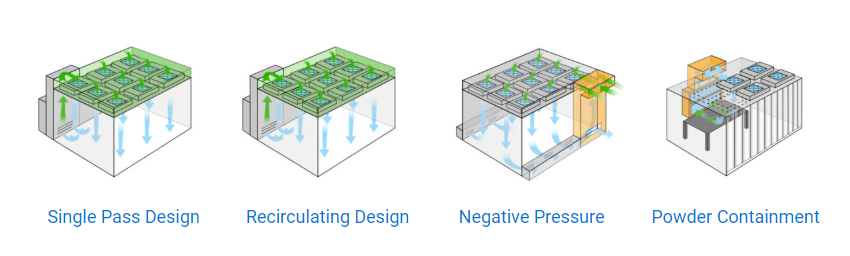

Each ISO Class level is 10 times cleaner than the next lowest classification. Moving up one cleanroom class from an ISO Class 8 to an ISO Class 7 cleanroom requires nearly twice as much air. Air filtration and conditioning is a significant factor in overall operating expenses. Overall square footage, the number of filters required, humidity, and air intake temperature all impact energy use. The efficiency of these systems is a direct relation to operating cost. A cost increase of 25% for each step in classification is expected. Generally, a recirculating airflow cleanroom incurs a larger initial investment, but is more efficient than a single pass cleanroom design.

What’s the Advantage of a Turnkey Cleanroom System?

Cleanroom control systems and electrical designs are critical, but so are considerations for structural, architectural, and application compliance. Turnkey cleanroom solutions with modular components empower easy adaptation of adjacent structures, cascaded classification of interior rooms, expandable compliance, and relocation.

What are the Most Popular Cleanroom Air Flow Designs?

Post time: Mar-19-2020